The QE Type Double Trolley Bridge Crane seamlessly integrates the core advantages of high efficiency, large capacity, high flexibility, and space-saving through the incorporation of two trolleys on a single bridge structure. It represents a highly efficient and intelligent solution designed for modern heavy industries to tackle complex material handling challenges, serving as a key piece of equipment for boosting production efficiency and enabling automated processes.

Features of the QE Type Double Trolley Bridge Crane

The double trolley design offers numerous advantages over single trolley cranes:

Exceptionally High Operational Efficiency:

The two trolleys can perform different lifting tasks simultaneously without interference. This enables assembly-line-like continuous operation, making it particularly suitable for busy workshops or warehouses.

Outstanding Lifting Capacity and Flexibility:

·Independent Operation: Each trolley has its own rated lifting capacity and can independently handle relatively lighter lifting tasks.

·Tandem Lifting: When transporting oversized, extra-long, or extremely heavy loads close to the crane's total weight limit, the two trolleys can perform tandem lifting using spreader beams or other specialized rigging. In this mode, the total lifting capacity is the sum of both trolleys' rated capacities (accounting for load imbalance factors), significantly enhancing operational flexibility.

Optimized Workshop Space Utilization:

Compared to installing two separate overhead cranes, the double trolley double girder crane requires only one set of metal structures (bridge girders) and one set of bridge travel mechanisms. This saves overhead space, reduces overall costs, and avoids potential interference issues between two independent cranes.

Advanced Control System:

This serves as the "brain" of the double trolley crane. The system must include:

·Precise Positioning and Synchronization Control: During tandem lifting, it ensures synchronized hoisting and travel speeds of both trolleys to prevent load tilting or slipping.

·Anti-Collision Function: Automatically monitors the distance between the two trolleys to prevent collisions during operation.

·Load Distribution Monitoring: During tandem lifting, it monitors the load borne by each trolley in real time to ensure it remains within safe limits.

High Safety and Reliability:

In addition to standard safety devices (such as limit switches, overload limiters, emergency stops, etc.), the double trolley crane incorporates specialized safety protections for dual-trolley collaboration, ensuring safe operation under complex working conditions.

Applications of the QE Type Double Trolley Bridge Crane

The QE Type Double Trolley Bridge Crane is widely used in scenarios requiring efficient, heavy-duty, and complex lifting tasks:

Thermal and Hydropower Plants: Used for the installation and maintenance of large components such as turbine rotors, generator stators, and steam turbine casings. The tandem lifting function is critical for handling these ultra-heavy and precision equipment.

Large Metallurgical Enterprises: In steel plants' rolling and continuous casting workshops, it is used for transporting and replacing ladles, steel billets, and large rolls, meeting the demands of high-efficiency continuous production.

Heavy Machinery Manufacturing: Employed in assembling large ship engines, mining machinery, pressure vessels, etc., facilitating the turning, positioning, and precise alignment of large workpieces.

Large Warehousing and Logistics Centers: Particularly in industries such as paper and building materials, it is used for simultaneously handling multiple paper rolls or large building material products, significantly enhancing loading and unloading efficiency.

Equipment Maintenance and Nuclear Power Applications: Inside nuclear power plants, it is used for maintaining and replacing heavy equipment within the nuclear island, requiring extremely high safety standards and precise synchronous control.

Ports and Shipyards: Although gantry cranes are more common outdoors, some large indoor dry docks or workshops use this crane for the assembly and transportation of ship sections.

-

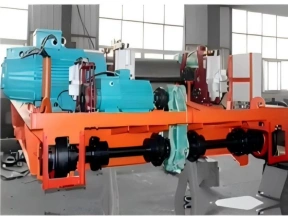

Trolley The mobile unit that carries the hoisting mechanism, traversing laterally on rails atop the main girders. The double-trolley design features two independent units capable of operating separately or in coordination for flexible lifting solutions.

Trolley The mobile unit that carries the hoisting mechanism, traversing laterally on rails atop the main girders. The double-trolley design features two independent units capable of operating separately or in coordination for flexible lifting solutions. -

Main Girder The primary load-bearing structure of the crane, spanning the workshop bay. Its box-section design provides sufficient strength and rigidity to withstand the hoisted load and the weight of the trolleys.

Main Girder The primary load-bearing structure of the crane, spanning the workshop bay. Its box-section design provides sufficient strength and rigidity to withstand the hoisted load and the weight of the trolleys. -

End Girder Located at each end of the main girders, supporting the entire crane structure. They house the wheels and drive mechanisms that propel the crane along the runway tracks.

End Girder Located at each end of the main girders, supporting the entire crane structure. They house the wheels and drive mechanisms that propel the crane along the runway tracks. -

Wheels:Load-bearing/travel components on end carriages & trolleys.High-strength steel, supports heavy pressure, motor-driven for smooth crane/trolley longitudinal/lateral movement.

Wheels:Load-bearing/travel components on end carriages & trolleys.High-strength steel, supports heavy pressure, motor-driven for smooth crane/trolley longitudinal/lateral movement. -

Hook The load-handling device that directly connects to the load. Forged from alloy steel for high toughness and strength, its secure design, often including features like a safety latch, is a critical element for safe lifting operations.

Hook The load-handling device that directly connects to the load. Forged from alloy steel for high toughness and strength, its secure design, often including features like a safety latch, is a critical element for safe lifting operations. -

Cab (Operator's Cab) The enclosed compartment from which the operator controls the crane. It is designed for clear visibility and contains all necessary controls, such as joysticks, pushbuttons, and indicator panels, for safe and precise operation.

Cab (Operator's Cab) The enclosed compartment from which the operator controls the crane. It is designed for clear visibility and contains all necessary controls, such as joysticks, pushbuttons, and indicator panels, for safe and precise operation.

Port Cranes

Port Cranes  Overhead Cranes

Overhead Cranes  Gantry Cranes

Gantry Cranes  Rubber-Tired Gantry Cranes

Rubber-Tired Gantry Cranes  Jib Cranes

Jib Cranes  Bridge Beam Launcher

Bridge Beam Launcher  Light-duty Cranes

Light-duty Cranes  Electric Hoists

Electric Hoists  Electric Winch

Electric Winch  Electric Flat Car

Electric Flat Car  Crane Accessories

Crane Accessories  Hydraulic Lifting Platform

Hydraulic Lifting Platform  General Manufacturing

General Manufacturing  Heavy Machinery Manufacturing

Heavy Machinery Manufacturing  Bulk Cargo Yard

Bulk Cargo Yard  Metallurgical Industry

Metallurgical Industry  Power Industry

Power Industry  Hydraulic Engineering

Hydraulic Engineering  Railway/Rail Transit

Railway/Rail Transit  Port Terminal

Port Terminal  Construction and Engineering

Construction and Engineering  Shipbuilding

Shipbuilding  Waste Recycling

Waste Recycling